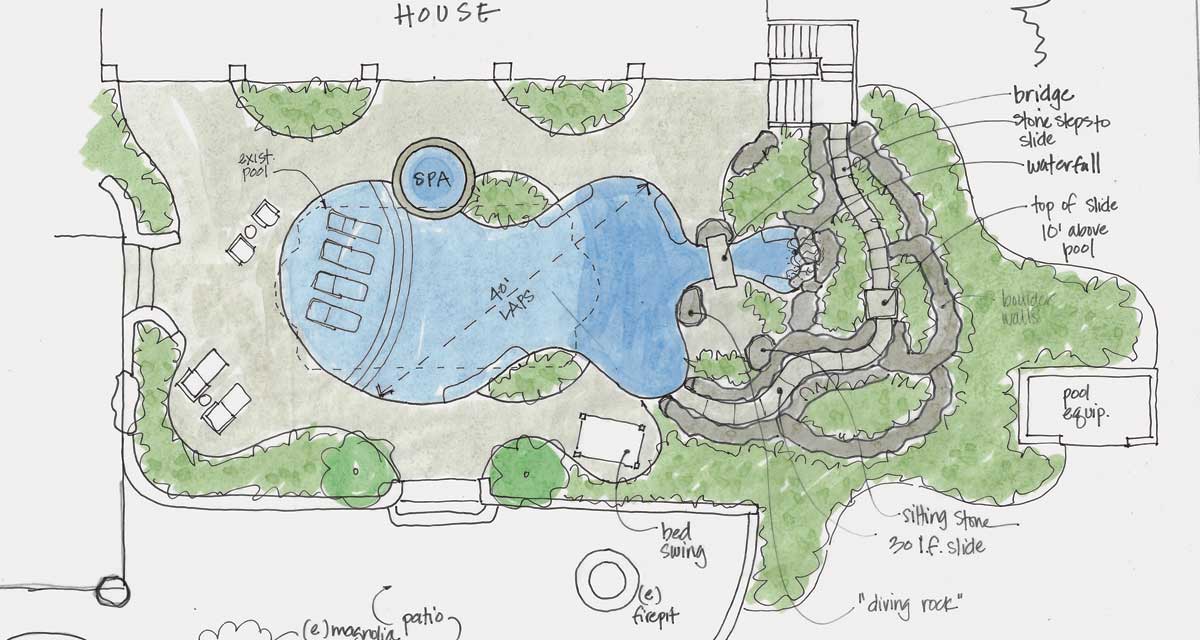

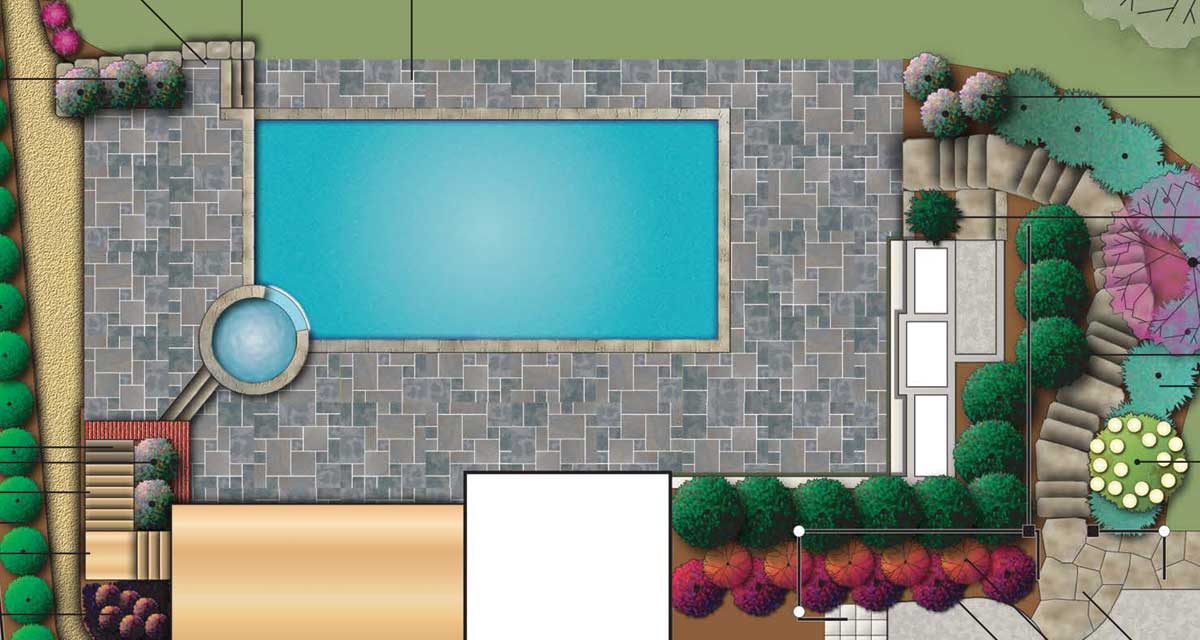

Design & Preparation

The Earthadelic team will walk you through the building process and answer your questions about owning a swimming pool. We will then put your ideas on paper as we work together to design a poolscape that meets any budgeting or design requirements. This is often a multi-step process, with numerous design refinements based on client feedback. We can even generate 3D renderings and virtual tours as a visual reference.

Excavation & Steel

Upon completion of your design, we will stake out the project and then begin the process of excavating the pool site and preparing the land for construction. Once the hole has been dug, we will use steel rebar to help with the formation of the pool walls and pool bottom. The steel serves as a skeleton that will help reinforce the formed concrete. Gunite pools are designed to last for many decades.

Plumbing & Electrical

Once the steel wireframe is in place, our licensed plumbers and electricians will lay the PVC pipe, electrical conduit, and wiring, as well as prepare the main drain and skimmer boxes. We recommend the most efficient equipment on the market, which will keep your pool clean and help reduce operating costs. Solar and geothermal heaters are just one of many ways your pool can be comfortable and eco-friendly.

Gunite & Equipment

Gunite is a special blend of concrete that is sprayed under high pressure to bind tightly around the steel. It is built up in layers and will slowly reveal the final shape of the pool. As the gunite cures, Earthadelic will continue to work on installing the filtration system and any other power equipment associated with your pool, such as pumps, valves, salt systems, pool heaters, lighting controls, etc.

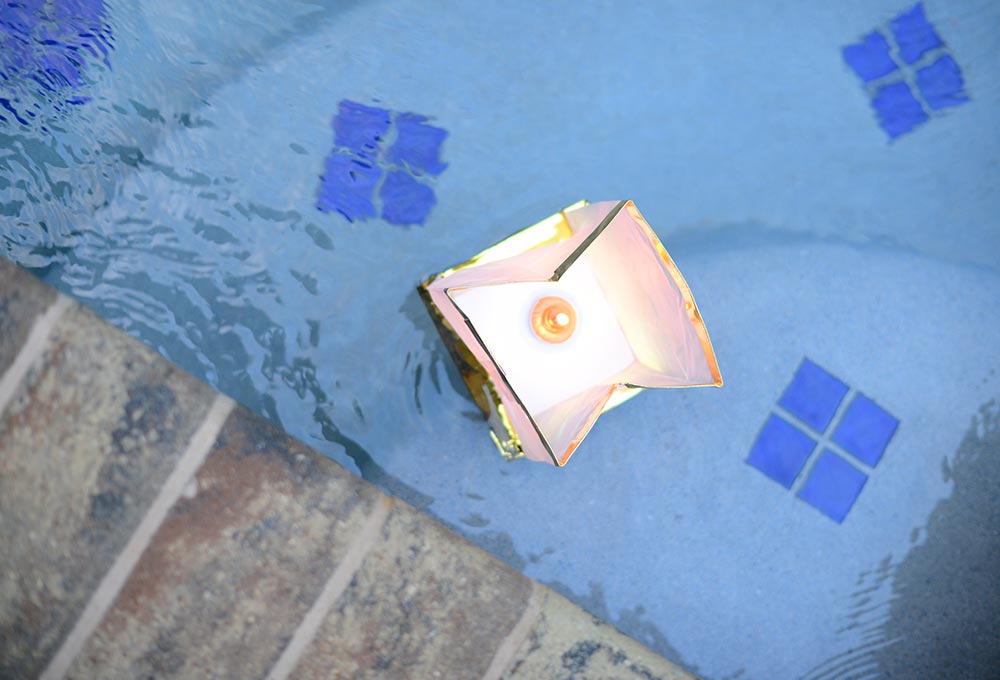

Tile & Coping

Next, we'll run a temporary band of flexible material along the top of the gunite to use as a template for the tile line. Once the tile is installed, we'll add the grout and then move on to the coping. Pool coping is the top edge around the pool that is walked on. Often, it's made with concrete pavers or sawn stone, but some designs call for concrete, brick, flagstone, travertine, or other exotic pool coping materials.

Deck & Plaster

After the coping has been laid, it's time to complete the pool deck surface and plaster the inside of the pool. Our pool experts will decide which should come first depending on material availability as well as your deck material. Plastering a pool is one of the last steps, and it's best to start filling the pool with water upon completion of the plaster setting. At this time, the finish must cure.

Start-up & Chemicals

Most manufacturers recommend letting the pool plaster finish cure for 30 days before adding salt, so Earthadelic recommends a traditional chlorine start-up for the first month of service. We'll balance the pool water for you, add all appropriate chemicals, and also brush the surfaces according to the manufacturers recommendations. If you've installed a saltwater system, we'll switch over when the time is right.